In the fast-evolving landscape of advanced manufacturing, the demand for precision, consistency, and operational efficiency has never been greater. Nowhere is this more evident than in metal stamping operations, where high volumes and tight tolerances are the norm — and where even the smallest imperfection, including subtle surface defects, can compromise safety, product integrity, or performance.

From automotive chassis components to aerospace brackets and electronic enclosures, metal stamped parts form the structural foundation of countless critical systems. The challenge? Maintaining exceptional quality standards at increasingly high production speeds, while reliably detecting a wide range of defects — from dimensional inaccuracies to scratches, dents, and coating imperfections — a feat that traditional inspection methods can no longer guarantee.

To stay competitive, manufacturers are turning to Machine Vision AI — an intelligent, automated inspection technology that is transforming quality assurance on metal stamping lines across industries by enabling comprehensive surface defects inspection with unmatched speed, precision, and reliability.

The Inspection Challenge in Metal Stamping

Metal stamping provides high throughput and exceptional repeatability; however, it remains susceptible to a variety of defects that can compromise product quality and performance. Common issues include:

- Burrs and sharp edges

- Surface defects such as scratches, dents, and inconsistencies

- Punching misalignments and incomplete forming

- Warping, bending, and deformation of part geometry

- Cracks and microscopic fractures

- Coating or finishing deficiencies

A significant challenge in inspecting the highly reflective metal surfaces. Intense glare and reflections can mask critical defects, complicating accurate detection. This issue is further compounded by the complex geometries of stamped components, which often include curves, recesses, and intricate details requiring multi-angle inspection. Additionally, many defects occur at a microscopic scale, demanding highly precise detection capabilities. Coupled with the requirement for real-time inspection to keep pace with fast production lines, these factors make traditional inspection methods increasingly inadequate for ensuring consistent quality.

Why Traditional Inspection Methods Fall Short

Manual inspection, while familiar, is inherently inconsistent, subjective, and time-intensive. Similarly, conventional machine vision systems often lack the adaptability and resolution required to detect subtle or hidden defects in metal stamped parts. Key limitations include:

- Reflective glare that obscures surface imperfections

- Single-angle inspection views that miss defects on complex geometries

- Micron-scale flaws that are invisible to the human eye

- High production speeds that outpace manual inspection workflows

- Static inspection setups unable to accommodate product variations

Consequently, many manufacturers experience elevated defect escape rates, costly product recalls, increased rework expenses, and persistent quality control bottlenecks.

A Game-Changer: Machine Vision AI for Stamped Metal Part Inspection

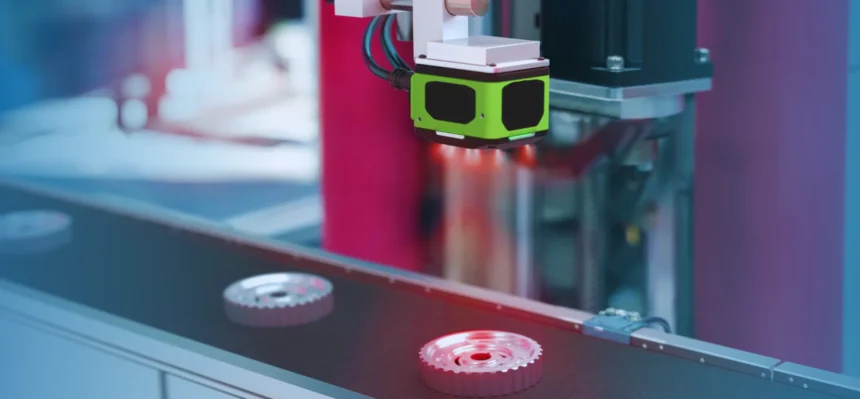

Machine Vision AI represents a highly scalable and intelligent solution engineered to meet the rigorous demands of metal stamping operations. By integrating high-resolution imaging, advanced lighting techniques, and real-time AI analytics, it delivers unparalleled inspection accuracy and efficiency.

Area Scan Cameras for Comprehensive Surface Inspection

In precision-driven environments like metal stamping, achieving full-surface inspection requires more than just speed — it demands accuracy, adaptability, and detail. Area scan cameras offer a robust solution by capturing high-resolution, full-frame images of each part in a single exposure. Unlike line scan systems, which rely on sequential scanning, area scan technology delivers a complete visual snapshot of the entire component in real time.

This capability is especially valuable for identifying microscopic defects that may appear on a wide range of surfaces and geometries, including:

- Flat surfaces where uniform inspection is critical for finish quality

- Recessed areas where defects can be easily overlooked without the right angle and focus

- Curved edges that introduce visual distortions and shadowing

- Complex contours with multi-dimensional features that require precise depth perception

By capturing the entire part at once, area scan cameras eliminate blind spots and ensure consistent, thorough defect detection — regardless of the part’s size, shape, or orientation. This all-encompassing visual coverage plays a pivotal role in maintaining quality standards, reducing false negatives, and enhancing inspection reliability across high-speed production lines.

Advanced Illumination Techniques for Enhanced Visual Clarity

Lighting plays a crucial role in inspecting highly reflective metal surfaces. Machine Vision AI employs specialized illumination methods to mitigate glare and reveal hidden defects:

- Structured Lighting: Projects precise patterns onto the part surface, highlighting deformations, dents, and subtle texture variations.

- Backlighting: Creates high-contrast silhouettes that accentuate holes, cutouts, and edge-related defects with exceptional clarity.

Together, these lighting techniques optimize contrast and detail, enabling reliable inspection of even the most challenging surfaces.

AI-Powered Software: The Intelligence Behind the Inspection

At the core of this solution is a powerful AI-driven software platform, capable of detecting, classifying, and documenting defects in real time. Key capabilities include:

- Instantaneous image analysis for rapid pass/fail decisions

- Deep learning algorithms trained to recognize a broad spectrum of defect types

- Customizable detection parameters tailored to specific tolerance levels and quality standards

- Continuous improvement through adaptive learning from operator feedback and new defect data

- Seamless integration with Manufacturing Execution Systems (MES) and Programmable Logic Controllers (PLC) for synchronized production control

This adaptive AI technology excels in dynamic, high-mix, and high-speed manufacturing environments, enabling manufacturers to maintain stringent quality standards without sacrificing throughput.

Optimized Workflow for Stamped Part Inspection

Image Capture with High-Resolution Area Scan Cameras

Strategically positioned, high-resolution scan cameras capture detailed images of each part from multiple angles, ensuring complete surface coverage — including hidden, recessed, or irregular features that are often missed by single-view systems.

Advanced Illumination for Surface Defect Visibility

Specialized lighting configurations — including structured lighting and backlighting — eliminate glare and shadows, revealing subtle surface imperfections such as scratches, dents, burrs, and warping that might otherwise go undetected on reflective metal surfaces.

AI-Based Real-Time Defect Analysis

At the core of the system, AI-powered software processes the captured images in real time, accurately detecting, classifying, and localizing defects with micron-level precision. Deep learning models adapt to evolving defect patterns and customer-specific quality thresholds, ensuring consistent inspection performance.

Automated Sorting and Decision-Making

Based on AI analysis, the system instantly determines whether a part meets the quality criteria. Defective components are automatically separated using precision sorting mechanisms — reducing reliance on manual inspection and preventing flawed products from reaching downstream processes.

Data Logging, Traceability, and Compliance

Each inspection is meticulously recorded, creating a comprehensive digital log of part quality. This traceable data is essential for audit readiness, regulatory compliance, and long-term quality control, offering manufacturers a transparent view of production performance.

Continuous Feedback for Process Optimization

Inspection results feed directly back into the system, enabling real-time adjustments to production parameters and ongoing refinement of the AI algorithms. This closed-loop feedback mechanism drives continuous process improvement and maintains alignment with even the most stringent industry standards.

Streamlined Workflow for Automated Metal Part Inspection

- High-Resolution Image Capture

Multi-angle, high-resolution area scan cameras capture detailed images of each part, covering all surfaces and hidden features. - Advanced Illumination

Structured lighting and backlighting eliminate glare and shadows, enhancing visibility of surface defects like scratches, dents, and burrs. - AI-Powered Defect Detection

AI software analyzes images in real time, detecting and classifying defects with micron-level accuracy and adapting to changing quality thresholds. - Automated Sorting

Parts are instantly accepted or rejected based on AI analysis, with defective components automatically sorted out to reduce manual inspection. - Traceability & Compliance

Inspection data is logged for full traceability, supporting audits, compliance, and long-term quality control. - Continuous Improvement

Feedback from inspection results drives real-time production adjustments and ongoing optimization of AI accuracy.

Key Benefits of Machine Vision AI for Stamped Metal Parts Inspection

Fully Automated, Round-the-Clock Inspection

Eliminate human fatigue and variability with 24/7 automated inspection. Machine Vision AI ensures consistent, unbiased quality control without interruption, maximizing throughput and operational efficiency.

Micron-Level Defect Detection

Advanced imaging and AI algorithms detect even the most minute flaws—such as micro-cracks, burrs, or surface irregularities—that are often invisible to the human eye or traditional inspection methods.

Real-Time Quality Monitoring and Control

Instant defect identification and classification allow for immediate feedback and corrective action on the production line. This reduces defect propagation, minimizes downtime, and enhances overall product quality.

Flexible and Scalable to Evolving Needs

The system is easily configurable to accommodate new part geometries, changing inspection criteria, and increased production volumes, making it ideal for high-mix, dynamic manufacturing environments.

Significant Cost Reduction

By minimizing rework, scrap, and returns due to undetected defects, manufacturers realize substantial savings in operational costs and improve their bottom line.

Actionable, Data-Driven Insights

Every inspection is logged and analyzed, providing valuable data for trend analysis, root cause identification, and long-term quality improvements. This empowers manufacturers to make informed, strategic decisions for process optimization.

In the era of smart manufacturing, quality assurance must be as fast, precise, and adaptive as the production lines it supports. Machine Vision AI delivers on all fronts — helping manufacturers achieve flawless output, minimize waste, and protect their bottom line.

Are you ready to bring intelligent inspection to your metal stamping process?

Machine Vision AI isn’t the future — it’s the new standard.